About the Business

HPS Product Recovery Solutions, (formerly known as Hygienic Pigging Systems), has their headquarters in Beeston, Nottingham. The company was started in a garage back in 1995 and has since grown into an internationally recognised engineering design and manufacturing business.

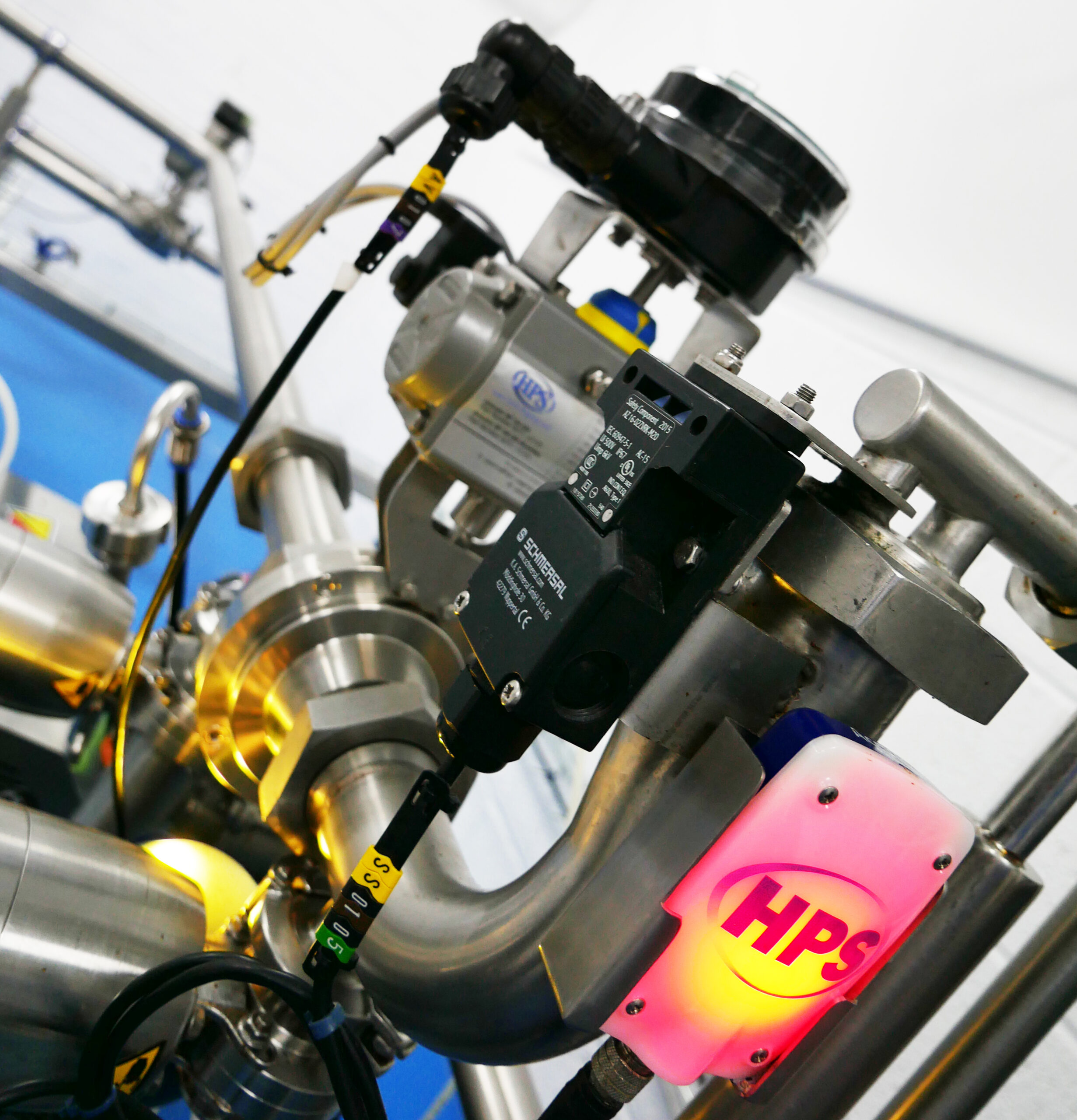

Specialising in advanced liquid product recovery technology (a type of ‘pigging’), and liquid transfer solutions, HPS helps companies across the world to increase yield, reduce waste, and improve efficiency and environmental sustainability when processing liquids as part of their product manufacturing processes. Their bespoke systems are trusted by an impressive list of multinational blue-chip clients including Coca-Cola, Nestlé, Unilever, L’Oréal, 3M, and Colgate-Palmolive, as well as smaller independent manufacturers.

Operating internationally, HPS has offices in the US and Australia, and a network of partners and agents supporting customers in Asia, Africa, Europe, and the Americas. Their continued focus on sustainability, product design and innovation, as well as customer support has made them a leader in their field.

With a dedicated team of 25 employees, HPS is led by Founder Gilbert Murphy, Executive Chairman Peter Elgar, and CEO Stevie Ker. Since 2023 the company has been recognised in several regional and national industry awards and in 2024, they received an Ecovadis Bronze Medal. In 2025 the company was proud to be 47th in the Sunday Times Top 100 Companies.

Challenges Faced

HPS has experienced significant success in recent years, but rapid growth has brought with it some major challenges. 2024 was a record-breaking year for the company, and with that momentum comes the need to continuously evolve.

Operating in a highly competitive sector, HPS must ensure that both its products and internal capabilities remain ahead of the curve. Maintaining sustainable innovation, addressing recruitment and training needs, and staying on top of changes in energy costs, tariffs, and global markets are all key areas of focus for the leadership team.

The solution and Impact

One of the ways HPS has tackled these challenges is through active engagement with the East Midlands Manufacturing Network (EMMN), delivered by the East Midlands Chamber.

Executive Chairman Peter Elgar has been a regular attendee of the Nottingham Manufacturing Network meetings since 2016. He values EMMN as a platform for industry insight, collaboration, and shared problem-solving.

Through EMMN, HPS has built strong connections with technical and operational peers, gained practical knowledge on industry challenges such as recruitment, training, energy, and tariffs, and taken part in collaborative opportunities. EMMN meetings offer HPS a space for peer learning, allowing them to understand how other manufacturers are tackling similar issues and provide time to reflect within a professional, friendly network.

They have also worked with EMMN partners like the University of Nottingham, and Make UK, even becoming a runner-up in the 2024 Make UK Award for Business Growth and Strategy.

Showcasing Success

and Building Connections through East Midlands Chamber

Being part of East Midlands Chamber has provided HPS with other opportunities to support business growth, innovation, and sustainability.

- Learning and Development: Participation in Chamber-run Accelerator Workshops has supported professional development across their team—covering areas like marketing, AI, and carbon literacy.

- Export Growth: International training sessions delivered by the Chamber have helped staff build expertise to support export activities in key international markets.

- Innovation: HPS has recently connected with the Chamber’s Innovation Services team

- Broader Engagement: HPS actively participates in other Chamber events, including the Manufacturing and Trade Conference, helping the team stay connected with regional and national trends.

Through the support of EMMN and the Chamber, HPS has not only accelerated its growth strategy, but also strengthened its internal capabilities, furthering its position as a leading innovator in sustainable engineering solutions.